Let's be honest: cooling system leaks are a pain. They're ugly, expensive to treat and they ruin the quality of your machinery. No company can afford that.

Sure, you can manage them. You can add coolant on a regular basis, but that's an expensive hassle. If you go for a hard repair, your 're looking at downtime and lost revenue. In many cases, you might not even have the budget for a hard repair, and/or you can't keep an inflated operating budget because you're managing the leaks, not fixing them. What can you do?

Industrial Seal Pro™ is the first solution specifically designed to

seal cooling system leaks in machinery of all sizes.

Industrial Seal Pro™ is a professional engineered solution designed to seal cooling leaks in your refrigeration system with industrial-strength bonds. Application is simple (installation directions are here), and Industrial Seal Pro™ is very inexpensive compared to a hard repair. Even if you’re not considering a hard repair, Industrial Seal Pro™ will pay for itself over time because you will reduce your operating costs by minimizing how often you have to add coolant to your system. Coolant is expensive, and you shouldn't play cat-and-mouse with a leaking system. There’s a difference between managing leaks and fixing them once and for all.

Industrial Seal Pro™ is a professional engineered solution designed to seal cooling leaks in your refrigeration system with industrial-strength bonds. Application is simple (installation directions are here), and Industrial Seal Pro™ is very inexpensive compared to a hard repair. Even if you’re not considering a hard repair, Industrial Seal Pro™ will pay for itself over time because you will reduce your operating costs by minimizing how often you have to add coolant to your system. Coolant is expensive, and you shouldn't play cat-and-mouse with a leaking system. There’s a difference between managing leaks and fixing them once and for all.

How does Industrial Seal Pro™ work?

Once installed in the refrigeration system, Industrial Seal Pro’s™ suspended particles shrink 15 percent and collect at the outside of the leak and penetrate inward, establishing a permanent seal on the outside of the leak. Industrial Seal Pro™ is engineered to react only with the leaking portions of your system – everything else remains unchanged.

Industrial Seal Pro™ Features

- Seals leaks

- Inhibits formation of rust and scale

- Keeps your refrigeration system clean

- Neutralizes pH imbalance

- Controls electrolysis

- Lubricates water pumps

- Compatible with ALL types and brands of coolant

- Conditions and enhances refrigeration system operation

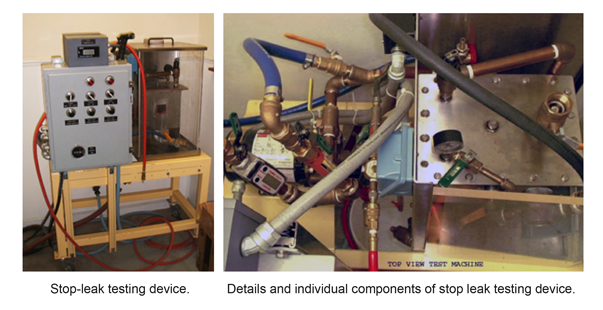

Industrial Seal Pro™ is ATSM D3147–06 tested.

With Shaler’s 100-year history of developing industrial stop leaks, you can be sure Rink Seal Pro™ is safe. Here are the results of testing Rink Seal Pro™ with Amalgatech, an independent third-party testing facility:

ASTM D3147 LABORATORY TEST

Standard Test Method for Testing Stop-Leak Additives for Coolants.

This test method covers screening procedures for the preliminary evaluation of leak-stopping materials intended for use in cooling systems.

- Gum/Gel Before: No

- Gum/Gel After: No

- Particles Before: No

- Particles After: No

- Screen: 0.020

- Final Round: 0.025

- Final Slot: 0.010

- Fluid Lost, mL: 495

The results of this test show that a 0.025 round hole and a 0.010 wide slot (crack) can be successfully sealed with this product.

Why Shaler?

Over 100 years ago, Shaler introduced an innovative product to stop leaks in vehicle tires. Since then, Shaler has continued to create stop leak solutions for nuclear submarines, locomotives and many other industrial applications.

When you choose Shaler, you’re not just choosing a product. You’re choosing over 100 years in stop leak expertise. To learn more, get in touch with us now.